I've seen many threads on many forums all about the same topic so I decided to write this troubleshooting guide to try to tie many of the snippets of info I've found dotted around into one FAQ/guide. Strictly speaking this isn't a guide, more a collection of tips but it should help you troubleshoot your engine if your having trouble with lift. This is far from comprehensive but should find the fault in most cases. These engines very rarely go wrong so I doubt many people will need to read this.

To begin with you really need to understand how lift works to be able to diagnose the problem, so we'll start at the very beginning. I'm going to assume that you have some knowledge about how an engine works and the names of the various parts and what they do. The target audience for this guide is an average DIY mechanic.

Disclaimer: I can not be held accountable for any damage caused to your car by following this guide and is intended for information purposes only!

How does lift work?

It's all in the rockers! (well mostly)

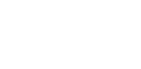

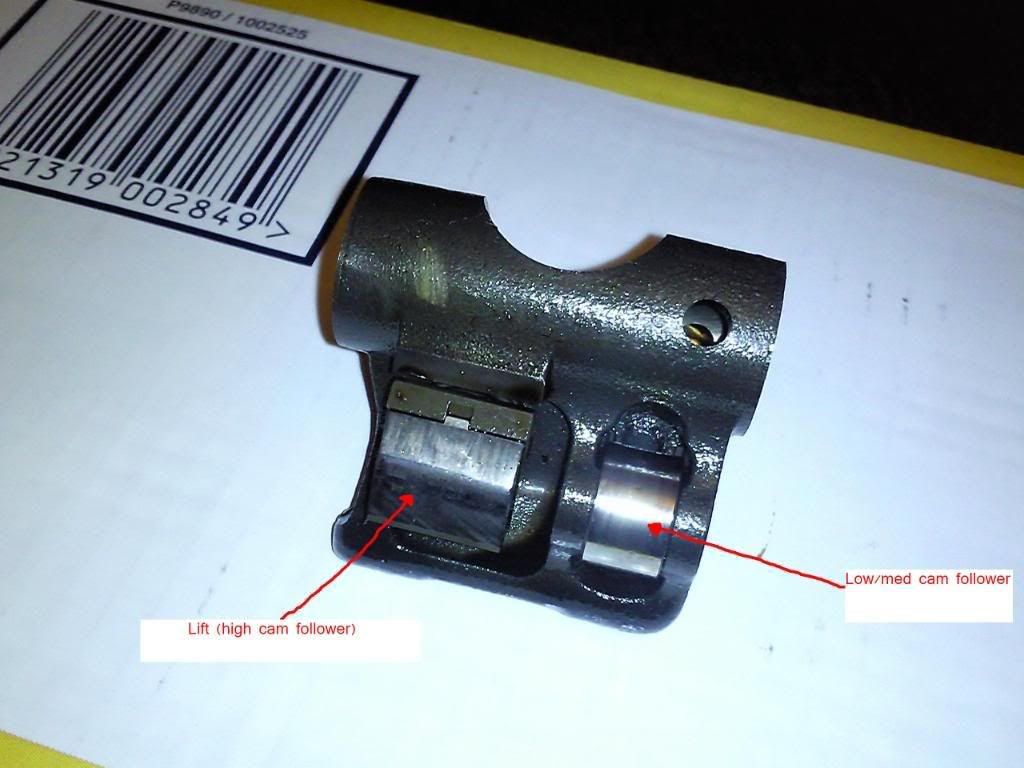

As you can see the low/med cam follower looks different from the high (lift) cam follower and that's because they are different! The low/med follower is a rigid roller and the lift follower is depressible (most of the time) and spring loaded. The key here is that the spring in the rocker is far weaker than the valve springs so when the cam rotates at low RPM the high cam profile just pushes the follower into the rocker while the force of the low/med cam profile operates the valves. I've tried to show this in the pics.

So how does the high lift cam profile come into play?

Well the rocker shafts are very important here because they are the oil lines that allow lift to operate. Under low speed operating conditions the rocker shafts are at low pressure. When the ECU receives the right inputs (more on this later), it sends a signal to the lift OCV (oil control valve) which operates causing a rapid increase in oil pressure in the rocker shafts. This forces a plunger in the rocker, commonly known as a lift pin, under the high lift follower locking it in place. This causes the valves to now be operated by the high lift cam lobe and Hey presto, Lift just kicked in y0!

Again have a look at the pics for things to be a little clearer.

Oil flows into this hole from the shaft.

Lift pin at low speed (low rocker shaft pressure). Note the bottom of thelift follower can be seen here. Obviously this isn't a normal rocker but ust think of it as a cut away for now!

In lift you can see that the lift pin has gone under the bottom of the high cam follower locking it in place.

The result:

What are the inputs the ECU needs to operate the OCV?

These are listed in any order:

1) A + or - speed. The engine will limit at 7000ish RPM and lift will not engage when stationary, apparently you can hit lift in reverse although I don't fancy testing that out.

2) Sufficient coolant temperature. The same thing will happen if the engine isn't warm enough to engage lift.

3) Oil pressure. As measured from the VVTL oil pressure sensor (white connector, nearest the top on the lift OCV housing)

4) Engine RPMs, the magic 6200rpm. As measured from the crank sensor.

Obviously if any of these sensors go wrong or the transmission of their signal is impaired (split wire ect) then there will be no lift.

Now we've gotten through all that you can start to diagnose where your fault lies.

First of all if there is an electrical fault as I've just mentioned then you almost defiantly will have a CEL and a code for your fault, not to mention some other associated symptoms. So my bet is if you're reading this, chances are this isn't your problem. On the other hand if you have a problem with lift and you have an unchecked CEL then get it checked! It will point you to your fault much easier than all this.

If you have a problem with lift and aren't lucky enough to have a CEL then I'm afraid it's going to be harder to find.

There are a few different types of lift problems: Lift is gone altogether, lift is weaker but still kicking in or lift is intermittently gone and finally lift is jerking or stuttering as the revs rise or there is a harsh jerky 'fuel cut' rev limit in lift. The next sentence is VERY important, if your car is anything other than smooth in lift (ie. Jerky, lumpy or a dip in power during lift) I personally would not use lift again or even the car completely until your sure it is fixed or checked out fully.

Lift has gone altogether

First off check all of your sensor connectors (it's very unlikely they are detached without a CEL), it might save you a lot of heart ache, time and money in the long run! Also try cleaning your MAF sensor, even though this won't cause lift to go on its own it's always good practice to get the car as healthy as you can before you start with the rest. I'm going to assume your car was warm when you tested it and you have already checked your oil level.

If lift is gone altogether and it's hitting a smooth rev limiter at 7000-7200rpm then chances are this is an OCV issue. Find a guide for OCV and OCV screen removal and cleaning and follow it. If the screen was dirty oil flow will have been reduced having an effect on oil pressure. This in effect will stop the lift pins from locking the high lift follower in place. Once they are clean, give it a try!

If they weren't dirty it is unlikely that dirt on the OCV and OCV screen were at fault. If the OCV is malfunctioning you should get a CEL but for whatever reason sometimes you don't. There is a quick test you can do to check your OCV is working. Take the connector off (with the ignition off!!!) and connect the two prongs to a 12v supply. If your OCV is ok then you should hear it 'click' as it operates and this is ruled out. If it doesn't click replace your OCV and your problem should be cured.

If you have had no luck here then it might be a good idea at this point to clean the lift oil lines using an appropriate pipe cleaning tool. Take the lift OCV housing off and clean the oil lines with a pipe cleaner (I'm not talking junior school arts and craft supplies here). If there is a blockage in the line it could be effecting lift and this should get rid of it.

If this still hasn't solved your problem then it's time to open the rocker cover and check the infamous lift bolts. Lift bolts simply hold the rocker shaft in alignment with the rockers so the oil paths are all lined up. You may have heard of these breaking and it does happen, when it does the rocker shaft rotates out of alignment and the oil can't actuate the lift pins in the rockers. This is simple to check and there are plenty of guides around. Before you start buy some new lift bolts, they are only £1.50 so you might as well put new ones in if your taking them out anyway! If you take your lift bolt out and it's broken then I'm afraid it's a long TSB fix if you can do this sort of thing yourself or a hefty repair bill to get the old bolt out.

If none of this helps read on.

Lift is weak or intermittent

First stop lift bolts! Then check the rest of the above. If it doesn't help read on.

Lift is jerking or stuttering as the revs rise or there is a harsh jerky 'fuel cut' rev limit in lift or you still haven't found your problem.

Open your rocker cover and check the condition of your cams. You are looking for excessive wear on the high lift cam lobe. I've shown this below as best I can.

Normal cam showing normal mild wear (this particular cam is an exhaust cam from my CTS and has done 67,000 miles)

Abnormal cam wear. Note the shiny appearance and in the close up the flatness and the slight lip on the right. This is the intake cam from my CTS, same mile and in very very poor condition.

Feel the cam lobe for groves or ridges, they should be smooth with no notches. If you can feel any this could well be your problem if not it could still be more serious.

Next inspect your rockers to make sure there are no bits missing! Try to feel behind them for anything broken off. Worn cams and broken rockers tend to go hand in hand so be thorough! If they are broken or your cams are worn then you may well have problems. This is the worst case scenario and requires a new set of cams and rockers.

If I were you I would not use your car until you have either looked at this thoroughly in the case of worn cams and possible rocker failure (or had it looked at professionally) and in the case of having broken rockers you need to have the cams and rockers replaced and find the bits of rocker before you use your car again.

I had worn cams but on inspection (albeit not very thorough) the rockers seemed fine. Unfortunately for me my rocker was broken out of direct view and eventually the lift pin and rocker debris found its way to a valve snapping it in half and making it look like this.

And here are the bits of my I4 rocker

This is why I wrote this troubleshooting guide. It took me AGES to find this info out and by the time I did and got my car booked in to be fixed it died and cost me a grand total of £1600 for a head rebuild.

If you have tried all of the above and still got nowhere and your cams and rockers are fine then I'm afraid you have me stumped and is beyond the scope of this guide but I hope it has given you some clues and at least ruled some things out.

If you need a pro I recommend YVSperformance as the guys in the north who know what they are doing with this engine. If your not in the north, call fensport or similar and ask who they recommend in your area, I'm sure you won't go far wrong.

Finally if I have missed anything out, you can think of anything to add or there are any glaring errors in here please bring it to my attention via PM and I will amend it ASAP.

Good luck with your car.

Dailey87